Precious Metal Recovery

Precious metals such as gold, platinum, and palladium are widely used in jewelry, investment, electronic components, and catalysts in automotive and chemical industries. With gold, platinum, and palladium prices near record highs, every gram recovered counts. By recycling and reclaiming these precious metals, you can unlock tremendous value, reduce operating costs, and secure a more sustainable supply. Our precious metal scavenger outperforms traditional materials such as commercial chelating ion-exchange resins. In direct comparisons, our scavenger recovered up to 40% more precious metals than chelating resins, resulting in greater recovery efficiency and lower operational costs. Better yet, our advanced sorbents are cost-competitive, offering superior performance without higher expense.

Put simply, our technology helps you capture more value from what others may throw away—turning waste into profit while advancing a more sustainable future.

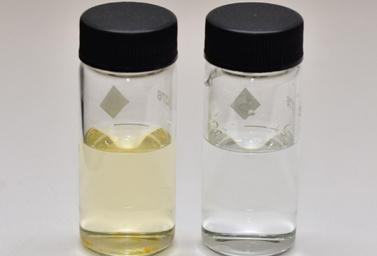

In one case study, 0.12 grams of our S-100 Amino Functionalized Silica was mixed with 200 grams of water containing 73.9 parts per million (ppm) of platinum (Pt) for 17 hours. The Pt concentration was reduced from 73.9 ppm to 17.4 ppm, recovering 76.5% of the Pt (Temperature 25.0oC and solution pH 3.08). The S-100 had an adsorption capacity of 94 mg/g and the spent S-100 contained 8.6% of platinum. You can see the difference before (left) and after (right) using S-100 in the following picture (Figure 2).

In the second case study, 0.12 grams of our S-100 was mixed with 200 grams of water containing 0.447 ppm of Pt for 17 hours. The Pt concentration was reduced to 0.00683 ppm (6.83 parts per billion, ppb), recovering 98.5% of the Pt in the solution. (Temperature 25.0oC and solution pH 3.16).

In both cases, Pt concentrations were measured with Inductively Coupled Plasma Mass Spectrometry (ICP-MS) by a certified third-party lab.